Looking for that next level of accuracy? Our high fidelity 3D scanning technology allows for incredibly detailed referencing for the design and manufacturing of parts. Our 3D scanner works by projecting a structured light pattern onto the object's surface, it reflects back to the scanner's sensors. The sensors capture the distorted pattern created by the object's surface geometry. By analyzing the distortion of the structured light pattern, the scanner's software calculates the precise 3D coordinates of points on the object's surface.

3D Scanning

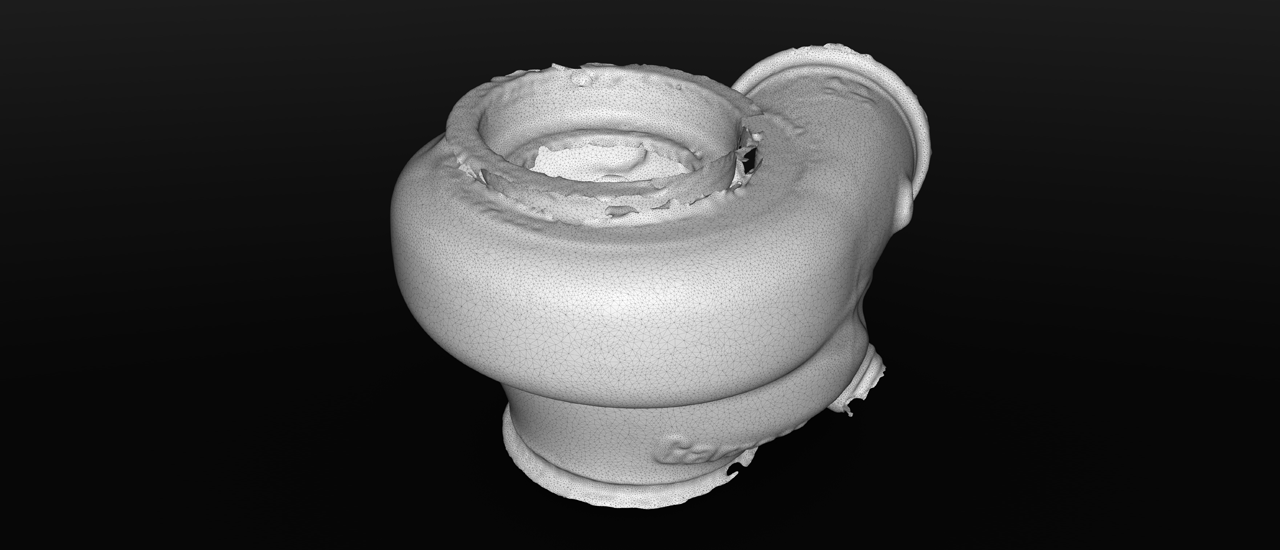

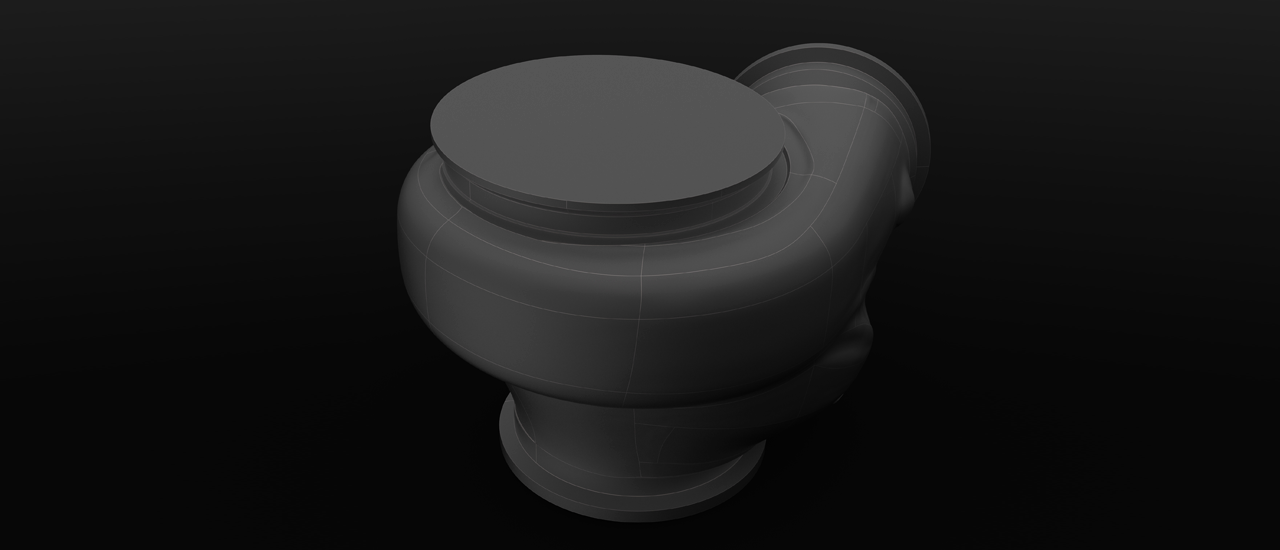

3D scans produce a very dense mesh. These mesh’s are made up of anywhere from hundreds of thousands, to millions of polygons. These highly detailed mesh’s are then used as reference material to build the most accurate CAD drawing possible ensuring precision which can only otherwise be achieved by taking hundreds of manual measurements.

raw 3D Scanned mesh

remodelled NURBS SOLID

3D scanning allows us to reverse engineer existing parts with complex geometry without the need for intricate measurements. This can be particularly useful for replicating rare or discontinued components. With 3D scanning, we can create precise digital models of existing components. This enables us to design parts that meet complex three dimensional constraints with ease.

COMMON 3D Scanning Applications

CAD Preparation and Prototyping

Reverse Engineering

Parametric 3D Modeling and Design

3D Part Archiving

Inspection for Quality Control

Scanning results are represented using free-form, unconstructed three dimensional data typically in the form of a point cloud or triangulated mesh. These images / scans are brought into a common referencing system where the data is compiled and merged into a complete model. This process is commonly referred to as the alignment or registration process. This can be performed during the scan itself or as a post-processing step.

The triangulated mesh is typically exported as an STL format, or can redrawn to Non-Uniform Rational B-Spline ( NURBS ) surfaces for CAD modeling.

How 3D scanning works

why use 3d scanners?

Scanning makes measuring complex parts incredibly easy

Having a 3D model creates a digital record that can be referenced at any time.

Reduce design iterations drastically with digital “test fitting”.